If you’ve dealt with a cracked, unresponsive, or “ghost-touching” car screen, there’s a good chance the issue wasn’t the LCD — it was the gel layer. Understanding the difference between gel-based and gel-free touchscreens can help you avoid repeat failures, wasted money, and unnecessary replacements.

This guide breaks down how each technology works, why gel screens fail so often, and why gel-free touchscreens are becoming the preferred long-term solution for vehicle infotainment repairs.

What Is a Gel Touchscreen?

Traditional automotive touchscreens use a gel bonding layer between the glass digitizer and the underlying LCD. This gel is designed to:

- Improve touch sensitivity

- Absorb vibration

- Allow light to pass through cleanly

When new, gel-based screens often work well. The problem is how they age.

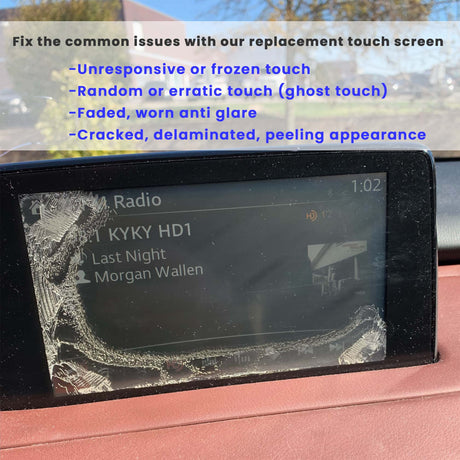

Why Gel Touchscreens Fail Over Time

Gel is not a permanent bonding solution. In vehicles, it’s exposed to:

- Heat cycles (summer dashboards, winter cold starts)

- UV exposure

- Humidity and condensation

- Constant vibration

Over time, the gel can dry out, liquefy, or migrate, leading to common failures like:

- Ghost touch (random inputs)

- Delamination (bubbling or separation)

- Dead zones or delayed response

- Cloudy or distorted visuals

This is especially common in systems like Cadillac CUE, Uconnect, and other large-format infotainment screens.

If you're experiencing these issues, consider one of our premium gel-free replacements.

What Is a Gel-Free Touchscreen?

A gel-free touchscreen eliminates the liquid bonding layer entirely. Instead, it uses:

- Solid-state optical bonding

- Laminated glass construction

- Precision adhesives that don’t migrate or degrade

The result is a screen that behaves more like modern smartphone displays — stable, predictable, and far more durable over time.

Key Differences: Gel vs Gel-Free Touchscreens

Durability

Gel-based screens degrade as the gel ages. Gel-free screens maintain structural integrity for years without internal breakdown.

Touch Accuracy

Gel movement can cause false inputs. Gel-free screens provide consistent, accurate touch response with no ghosting.

Heat Resistance

Gel is sensitive to temperature extremes. Gel-free construction handles dashboard heat far better.

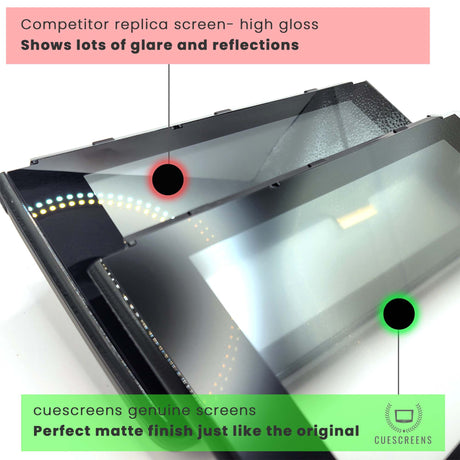

Visual Clarity

As gel breaks down, screens can look cloudy or uneven. Gel-free displays maintain sharp contrast and clarity.

Long-Term Reliability

Gel screens often fail again after replacement. Gel-free screens are designed to be a permanent fix, not a temporary repair.

Why Dealers Still Use Gel Screens

Many dealerships replace the entire infotainment unit, even when only the touchscreen has failed. These replacements often use the same gel-based design, which means:

- Higher cost

- No improvement in failure rate

- Risk of the same issue returning

Gel-free upgrades aren’t always offered because they require component-level solutions rather than full module swaps.

Are Gel-Free Touchscreens Worth It?

For most vehicle owners, yes — especially if you plan to keep your car.

Gel-free touchscreens are ideal if you want:

- A long-term fix instead of repeat repairs

- Improved touch accuracy

- Better heat resistance

- OEM-level or better performance

They’re particularly valuable for high-failure systems where gel degradation is the root cause of the problem.

TL;DR

- Gel touchscreens rely on a liquid layer that breaks down over time

- Gel-free touchscreens use solid bonding for better durability

- Gel failure causes ghost touch, delamination, and dead zones

- Gel-free screens are more heat-resistant, accurate, and reliable

- For long-term ownership, gel-free is the smarter choice

If touchscreen failure keeps coming back, the issue may not be how it was replaced — but what technology was used.

![[Premium] Upgraded Gel-Free Cadillac CUE Replacement Touch Screen Display-Cuescreens](http://www.cuescreens.com/cdn/shop/files/7c1892_b5fcaf040dfe42abb289e47b1fa91ab9_mv2.png?v=1738265347&width=460)

![[Premium] Upgraded Gel-Free Cadillac CUE Replacement Touch Screen Display-Cuescreens. Supports Proximity Sensors.](http://www.cuescreens.com/cdn/shop/files/7c1892_7faa9297eab444d5a99838357b9c178c_mv2.png?v=1764720901&width=460)